Sourcing Authentic Shurflo Pump Parts

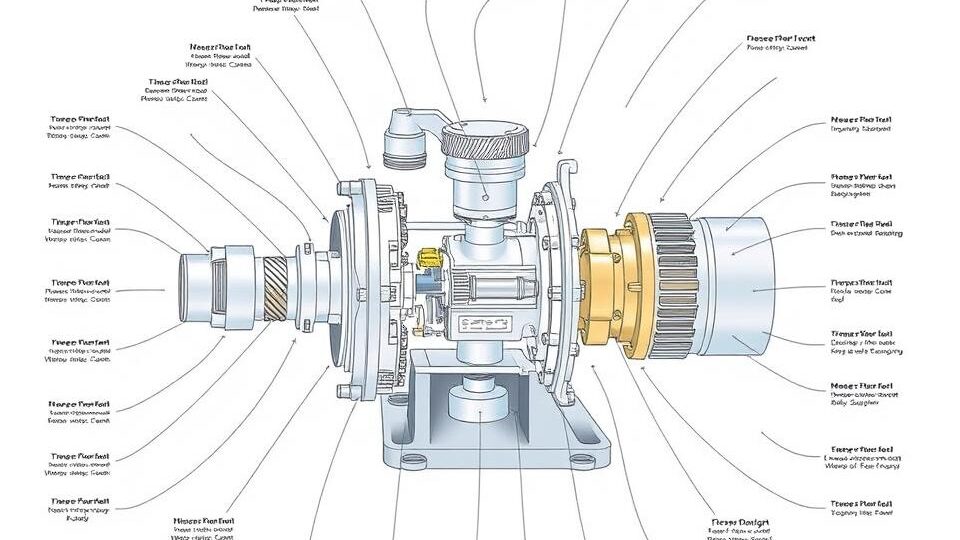

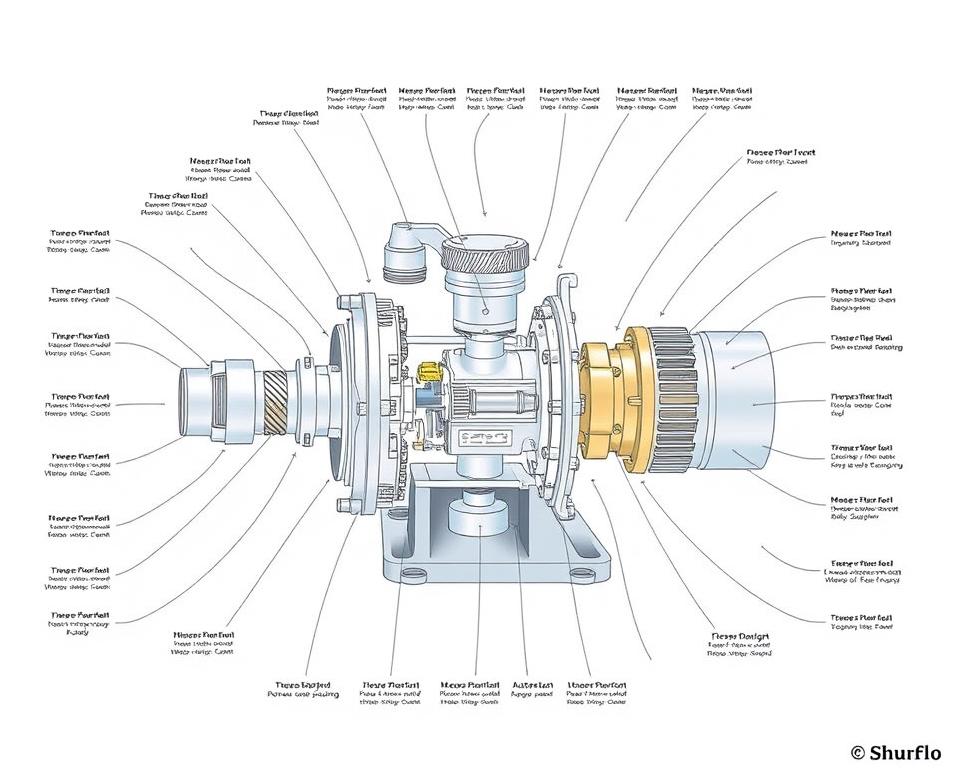

Shurflo Fluid Pump Schematic – Installation Parts Supply

Improper installation of Water Pump systems can significantly lower their performance by up to 30%. It’s essential to grasp the operation of the Shurflo Pump schematic for optimal operation and longevity. Each component within the diagram fulfills a key function in the operation of the Pump. We will explore the importance of grasping these Shurflo 8000 pump parts, utilizing the diagram to show their assembly and how they function collectively.

Installation Components Supply is your primary source for every Shurflo Pump part needed for installation and upkeep. Gaining knowledge from the Shurflo Water Pump parts diagram allows users to skillfully perform installation and servicing. This foundation aids in making wise selections for the optimal and reliable performance of their water pumps.

Grasping Shurflo Water Pumps

Shurflo Water Pumps are at the nexus of ingenuity and practicality, fulfilling the requirements of diverse applications. This portion seeks to provide an in-depth overview of Shurflo Water Pump models, their distinct functions, and the benefits of choosing these devices. They are renowned for their advanced technology and performance.

Overview of Shurflo Pump Types

Shurflo’s assortment comprises pumps like the membrane and horticultural series, designed for multiple needs. The membrane models are acclaimed for their sturdy design and efficiency in moving liquids. Examples such as the 2088-343-135 and 2088-343-500 offer powerful output with impressive flow and pressure capabilities.

The horticultural series, conversely, is designed for optimal fluid conveyance in agricultural settings.

Uses of Shurflo Pump Systems

The versatility of Shurflo Pump systems enables their use in a diversity of environments. They are commonly used for:

- Farming: Provides solutions for watering and nutrient application.

- RVs: Guarantees uninterrupted Water Pump service with safe pressure levels.

- Residential: Ideal for yard upkeep and home Water Pump installations.

This versatility enables these devices to integrate smoothly into diverse configurations, demonstrating their multifunctionality.

Merits of Choosing Shurflo Pump Systems

Opting for Shurflo Pump systems brings several perks. Their automatic priming function removes the hassle of manual priming. They also have resilience to chemicals, ensuring longevity in harsh environments. Readily available Shurflo membrane Water Pump parts streamlines servicing, boosting service life while reducing idle periods. Further advantages of Shurflo Pump systems consist of:

- Steady output adjustable to various pressures.

- Easy installation supported by the Shurflo pumps parts catalog.

- Multiple fitting types ensuring compatibility with current systems.

With these characteristics, Shurflo Pumps ensure efficiency and reliability. They maintain uninterrupted operation, providing users with confidence in their functionality.

Shurflo Water Pump Diagram and Its Importance

The Shurflo Pump schematic is essential for understanding its components and functions. By studying the Shurflo Pump schematic, users can put together, debug, and maintain efficiency. This diagram is vital for locating the needed Shurflo Pump parts. Proper arrangement facilitated by the schematic guarantees peak performance.

Essential Elements in the Diagram

The Shurflo Water Pump assembly diagram showcases essential components required for effective function:

- Motor: The motor, the heart of the Pump, propels the rotor, delivering flow rates between 41 and 168 GPM.

- Membrane: Helps sustain consistent flow and pressure.

- Check Valves: Key to stopping reverse circulation, these devices secure that water moves correctly.

- Casing: With a maximum pressure of 200 PSI, the housing maintains structural integrity.

How to Read the Shurflo Water Pump Diagram

To analyze the Shurflo Pump diagram, one must observe distinct symbols and markings:

- Study the layout of parts shown in the schematic.

- Identify the flow direction as shown by arrows among parts.

- Examine the remarks for information on wiring dimensions and mounting configurations.

Familiarity with this diagram is vital for efficient construction, servicing, and determining required elements.

Fitting Shurflo Water Pumps

Fitting a Shurflo Water Pump can make any water system more functional. Understanding the required procedures and parts is vital for a good installation. This guide outlines key actions and required instruments for a effective assembly.

Step-by-Step Guide to Installing a Shurflo Pump

- Begin by gathering all tools for shurflo pump installation. Ensure possession of tools such as a suitable screwdriver, wrench, and 50-mesh strainer.

- Attach the 50-mesh strainer to the inlet of the Pump. It is advisable to employ a flexible hose when linking the inlet to reduce fitting stress.

- Use a 1/2” to 3/8” barb splicer for securing tubing connections. To deter leaks, select strengthened tubing paired with Oetiker clamps.

- Connect the Pump to an adequately grounded electrical outlet. A professional electrician should handle this to meet regional standards.

- Charge the accumulator tank with 50 PSI of clean air or nitrogen. This is crucial for optimal pressure output.

- Place a SHURflo 65 psi water pressure reducer valve at the inlet to maintain appropriate pressure conditions.

- Complete the installation by linking all parts. Ensure the motor’s amperage rating is not surpassed; use thermal breakers for added protection.

- Run a diagnostic test and confirm the pressure switch works as intended.

Installation Essentials: Tools and Parts

| Component | Details |

|---|---|

| 50-mesh filter | Strains particles at the Pump’s intake for maximum efficiency. |

| Flexible hose | Preferred for inlet use, minimizing pressure on connectors. |

| Barb connector | Provides a secure 1/2” to 3/8” tubing linkage. |

| Accumulator tank | Charged to 50 PSI to ensure stable operation. |

| Pressure switch | Manages Pump function according to pressure needs. |

| Electrical supplies | Required for safe connections, ensure compliance with local electrical codes. |

| 65 psi SHURflo valve | Lowers incoming water pressure to stabilize Pump function. |

Resolving Typical Issues with Shurflo Pump Systems

Mastering issue resolution for Shurflo Pumps boosts overall efficiency. This segment offers a problem-solving manual. It guides users through resolving typical malfunctions to maintain uninterrupted function. Issues such as pump functionality, water flow, and noise are tackled with practical solutions.

Frequent Faults and Corrections

Various conditions may result in malfunctions with Shurflo Pumps. Here is a list of frequent problems with corresponding remedies:

- Pump operates without liquid movement: Assess the water supply level, inspect piping for clogs or impairments, ensure adequate priming, and test Pump performance.

- Pump won’t turn on after winterization: Revisit correct winterizing steps, check that valves remain open, confirm wiring integrity, and look for any component damage.

- Pump intermittently starting and stopping: Inspect for leaks, check for air in the system, ensure appropriate pressure settings, and verify the functionality of the pump and pressure switch.

- Pump producing excessive noise: Examine connections for looseness, install supportive padding, shield pipes, and confirm accurate installation.

Shurflo Pump Diagnostic Manual

A complete Shurflo Water Pump troubleshooting guide assists users in quickly identifying issues. Below is a summary table of common problems with solutions:

| Common Issue | Possible Reasons | Remedies |

|---|---|---|

| Operation without liquid movement | Deficient water supply, clogs, incorrect priming | Examine reservoir, review piping, confirm Pump operation |

| Failure to start | Improper winterization, closed valves, electrical issues | Reassess winter steps, ensure valves are open, verify wiring |

| Intermittent cycling | System leakages, trapped air, incorrect pressure settings | Examine for leakages, eliminate air, modify pressure controls |

| Noisy pump | Loose connections, inadequate installation | Tighten connections, add padding, insulate pipes |

Grasping the shurflo pump exploded view enables users to locate malfunctioning components is key to proper troubleshooting. Observing these steps guarantees proper maintenance and dependable functioning.

Final Thoughts

Comprehending the Shurflo Water Pump diagram is key for optimal Pump operation.

Utilized in various fields like RVs and agricultural spraying, efficient setup is crucial for dependable outcomes.

Knowledge of the schematic’s components enables proficient assembly and upkeep of systems.

For acquiring every necessary Shurflo Pump part and service, Installation Parts Supply is unrivaled, offering comprehensive support, ensuring access to essential tools and components. This aids in successful installations. By adhering to proper plumbing, wiring, and upkeep of parts like the strainer, the operational life and efficiency of the Pumps are boosted.

This article arms users with the necessary knowledge to optimize Shurflo system performance. Employing Shurflo Pump technology alongside these installation recommendations readies users to overcome any obstacles confidently.